|

|

|

BREAKING TECHNOLOGY

?... Possible Reverse Osmosis...?

For Ethanol Water Separation

______________

The new reverse osmosis technology is made possible by the

combination of a layer of ZEOLITE structure, fused to the surace of a ceramic cylinder.

Or by a polymeric micro tubular membrane.

Simple enough to state however the technology took years of development and looks very promissing.

It will not replace the good old Charles 803 completely since the use of distillation will

always occupy a very big space in the home production of ethanol as well as in large corporate operations.

- CAUTION..., CAUTION..., CAUTION...

- DON'THROW YOUR CHARLES 803 TO THE JUNK PILE JUST YET

- RO HAS BEEN RIDDLED WITH SCAMS AND PROBLEMS, SINCE IT STARTED SOME 30 YEARS AGO

- MOST STATES HAVE PASSED LAWS TO CONTROL CLAIMS MADE BY FAST SELLERS

- WAIT FOR THE TESTS RESULTS DONE BY DONALD FRANSON,

- HE IS VERY GENUINE AND HONEST

- GOSEE> http://tech.groups.yahoo.com/group/alcoholfuel/

- My assesment is that this technology will dribble down to us within the next decade

- It is still in development by a handfull of daring very specialised corporations

- With predictions of Refinery market reach by 2010

- Farmers and doodlers by 2020....

- If you feel you are being had, reach for your phone and take action.

- You will find instant support in most states.

- But in all cases, be prepared to sweat bullets.

- Not for the faint at heart, you will need practice

- This is a very high-tec unproven process

- The start up could be very frustrating

- Just like you did in your first Distillation attempts...

- Communicate lots, and share lots more

- Pioneers will be pioneers, and there ar lots of stumps...

- The end results are well worth the effort

- From 40 some years at developping, I can safely state:

- The rewards are equal to the hardships and sweats

- Multiplied by the efforts.

- And equal to the dream itself

- ( Nothing to do with money )

- For the love of the ethanol movement, and all those taking

part in it.

- ANY AND ALL SELLERS WHO CLAIM THIS TECHNOLOGY WORKS WELL

- ARE ADVISED TO CONSULT WITH THE AUTHORITIES AND

- BE PREPARED TO REIMBURSE UNSATISFIED CUSTOMERS

- BECAUSE THIS TECHNOLOGY HAS NOTHING AS EASY ABOUT IT,

- AS MOST ADVERTISEMETNTS CLAIM

______________

STATE OF THE TECHNOLOGY

AS OF JUNE, 2007

There are presently two mainstream

developpers, who claim to this technology, yet they foresee marketting it it for 2008 to 2020

The other and most interesting in its presentation, and well explained defininitons

is: VAPERMA and here are links to their filclip about RO tech:

______________

Mr Donald Franson from the Forum: Alcoholfuel

Is presently raising funds to purchasse a RO unit that employs this new technology.

He will then run a full complement of tests over a few months time period to prove the claims

of the supplier.

Please visit his forum and follow this breaking technology that will change the way we see

Ethanol production.

In some cases, ethanol producers have to refrain due to the limitations brought on with the

use of a still, and boiler.

This technology will definitely open new doors for the ethanol movement.

______________

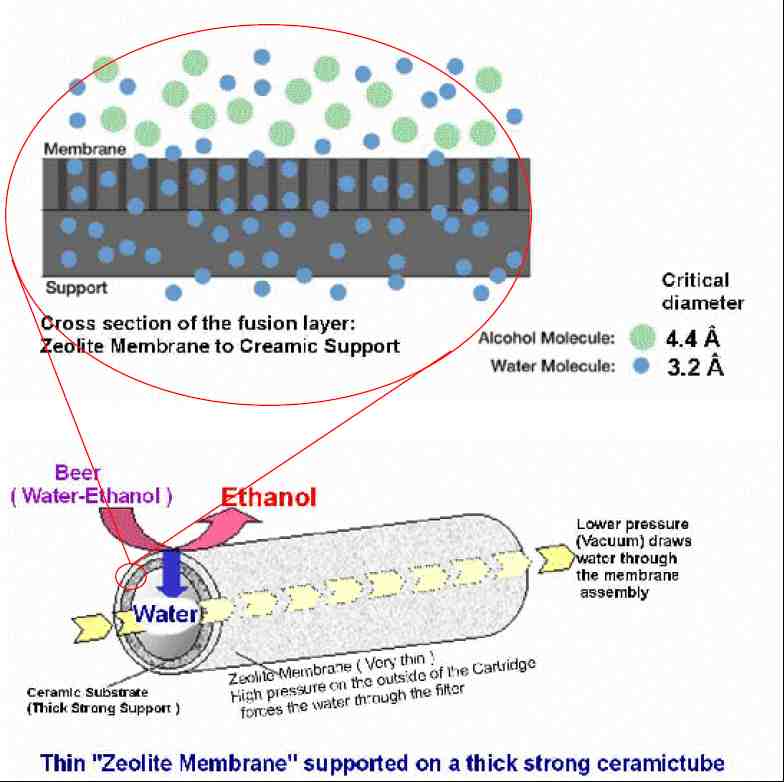

Here is a brief run down on how the process works

according to BRNI:

The Ethanol molecules ( in Green ) are too big to pass through the thin Zeolite surface.

But the smaller Water molecules ( in Blue ) pass

through the thin Zeolite surface then pass freely through the much thicker and stronger ceramic

substrate which has pores that are larger than the Zeolite

|

|

|

BNRI PROCESS

Although zeolite had been well-known

material to be used as absorbent, catalysts or ion exchanger for a long period, none had achieved to industrialize large scale

its membrane technologies without defects. We developed such zeolite membrane and separation processes with it.

Zeolite consists of 3-D mesh-like structure

where silicon oxide and aluminum oxide covalently share oxygen atom. Its mesh “eyes” stack regular array of tiny

pores in 3-D space. Those pores form channels at 0.4 to 0.8 nm width, which looks like a nano “jungle gym.”

Zeolite allows having various crystalline

forms of the mesh sizes and shapes depending on inclusion ratio of silicon and aluminum and their physical chemical properties

vary. While BNRI conduct to form membrane using variety of zeolite, we successfully commercialize A-type zeolite membrane.

A-type zeolite includes silicon and

aluminum at 1 to 1 ratio and its pore size is 0.4nm diameter. Since it has relatively high hydrophilic surface, it effectively

separate water from an aqueous organic solution.

|

|

|

|

|

|

|

|

|

|

|

|

Enter supporting content here

|

|

|

|